Components for bridges and structural constructions

This project, aimed at the civil engineering and architecture sector, involves the design and manufacture of a series of structural logistics components that can be integrated into bridges and buildings. The components are designed to provide greater movement flexibility and torsional capacity, offering five times the durability compared to steel, while also contributing a distinctive aesthetic touch.

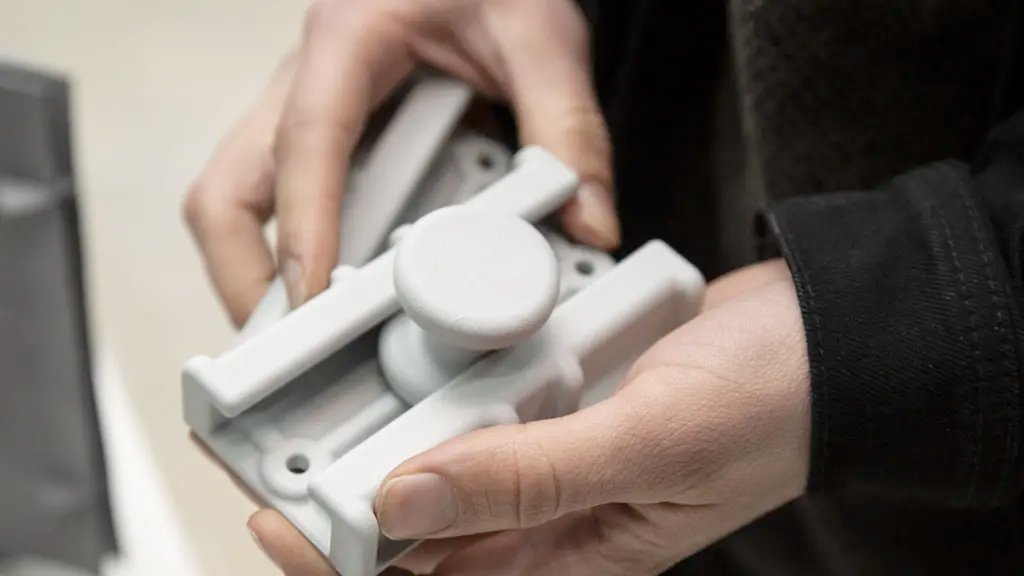

The components, designed in 3D by S3 Advanced Engineering, are capable of maintaining the shape of metal tubes which, when exposed to drastic environmental temperature changes, tend to expand and contract. They allow for deformation of up to 4mm in any direction, thereby helping to prevent potential structural damage.

Conventional components, made of galvanized metal and coated with zinc, tend to lose their protective layer and rust over time due to environmental exposure. This means they require regular maintenance—something that is not necessary with components produced through additive manufacturing. This solution is not only innovative and aesthetic, but also highly functional and effective in every way, significantly reducing maintenance, labor, and logistics costs.

Another key feature of the project is that, being made from a lighter material, the components are much easier to install, reducing the need for labor.