Proyecto KYK

Description

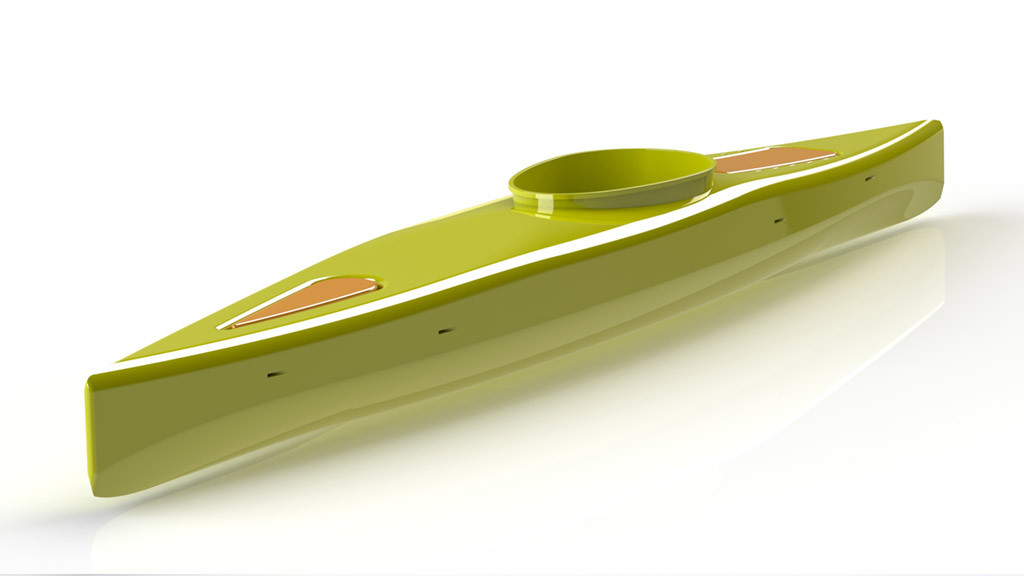

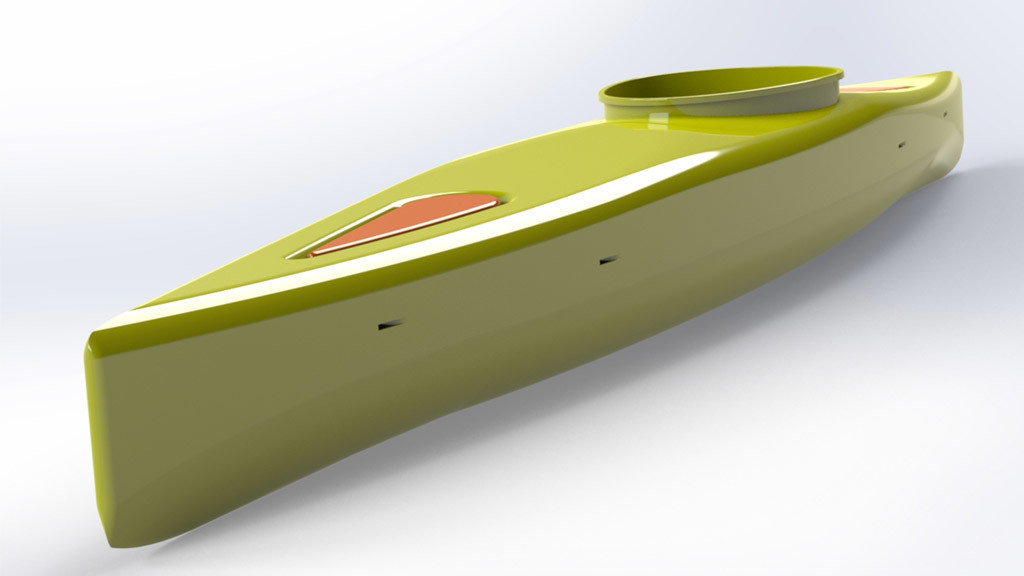

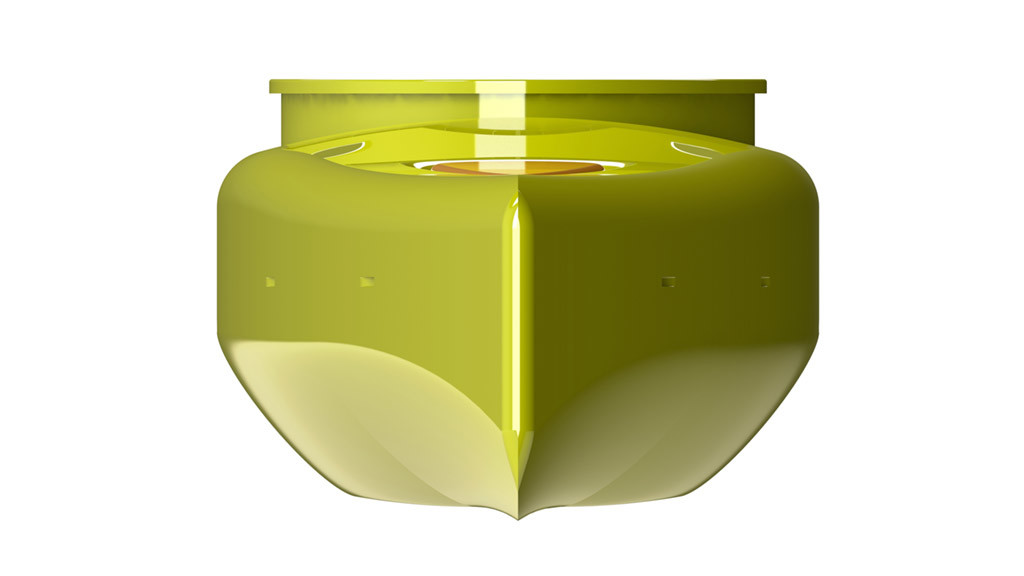

Thanks to the variability of thickness in different areas of the canoe, the kayak is lighter than the usual ones, going from a standard weight of 26 kg to 18 kg. By designing and producing it with additive manufacturing (industrial 3D printing), internal crews, support structures and sealed bulkheads have been added, something impossible to find in traditionally manufactured designs.

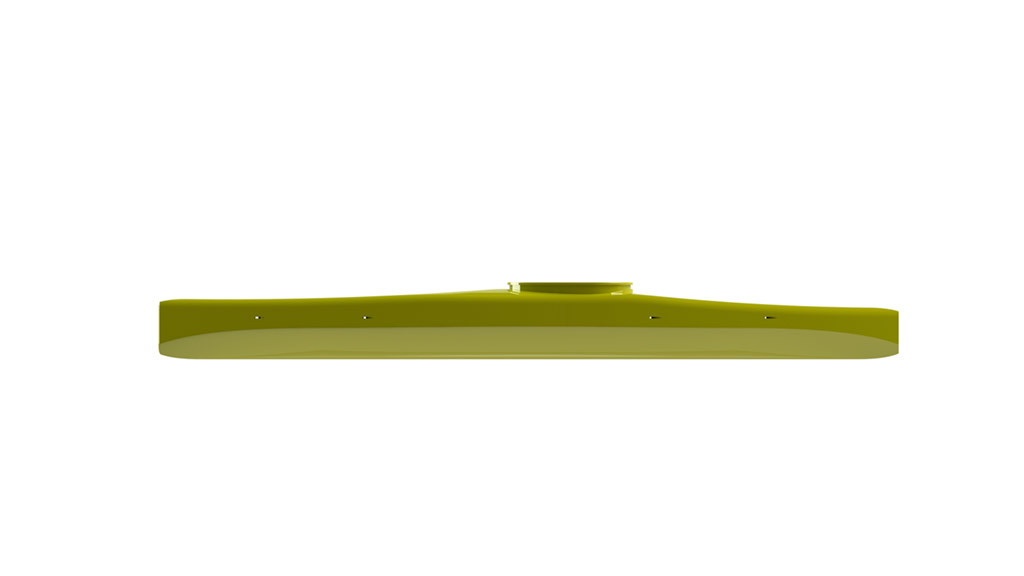

The design has been carefully calculated to cut the water with maximum efficiency. The drag, both water and air, has been calculated and perfected through simulations to reach a point where we find optimization and adequacy in each 2 cm2 of the kayak. It is a perfect kayak for long distances, since it is designed and thought so that its performance is impeccable in choppy waters, cross winds and currents.